General Application Gasketing

KLINGERSIL® C-4401 |

|

• Synthetic Fiber Typical values refer to 1/16" material See graphs for temperature & pressure limits |

|

Creep Relaxation ASTM F38B (1/32") |

20% |

Sealability ASTM F37A (1/32") |

<0.25 ml/hr |

Gas Permeability DIN 3535/6 |

<0.5 ml/min |

Compressibility ASTM F36J |

7% |

Recovery ASTM F36J |

50% minimum |

Klinger Hot Compression Test |

|

Thickness Decrease 73°F (23°C) |

10.5% initial |

Thickness Decrease 572°F (300°C) |

17% additional |

Weight Increase |

|

ASTM F146 after immersion in Fuel B |

|

Thickness Increase |

|

ASTM Oil 1, 5h/300°F (149°C) |

0-5% |

ASTM Oil IRM903, 5h/300°F (149°C) |

0-5% |

ASTM Fuel A, 5h/73°F (23°C) |

0-5% |

ASTM Fuel B, 5h/73°F (23°C) |

0-7% |

Dielectric Strength |

|

ASTM D149-95a |

14 kV/mm |

ASTM F104 Line Call Out |

F712121B3E12K6M5 |

Leachable Chloride Content |

|

Density ASTM F1315 |

112 lb/ft3 (1.8 g/cc) |

Color (Top/Bottom) |

Green |

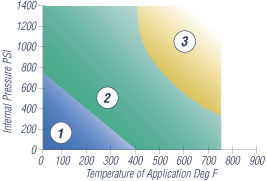

Pressure & Temperature Graphs (Click here to learn more about graphs) Liquids

|

|

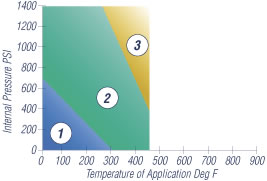

Gases & Steam

|

|